Particle size analysis of calcium carbonate products

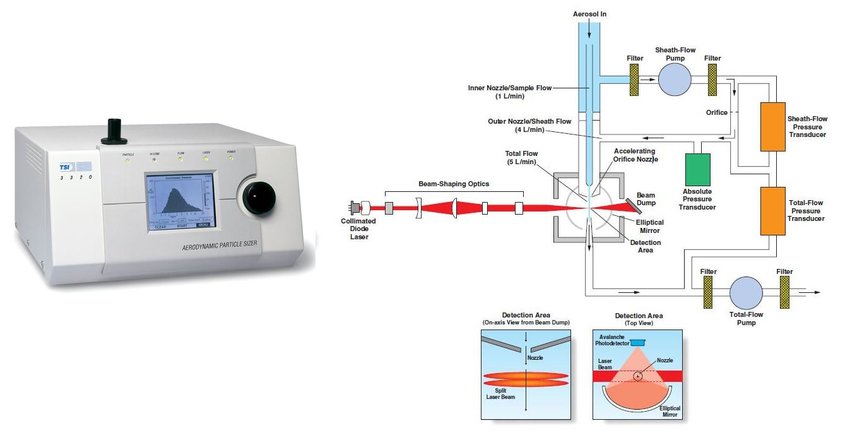

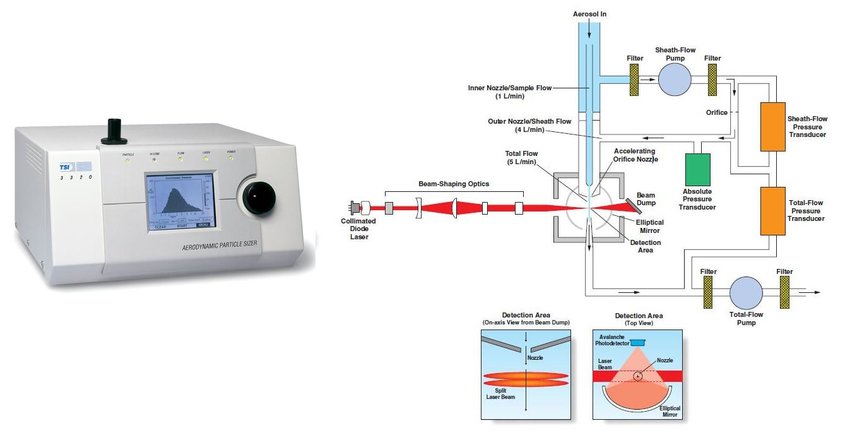

Physical analysis of particle size or the same particle size shows the frequency of particle dimensions in the powder and is usually reported based on

Emarat Mine company was established in 1989 ; its main activity is mining, processing, and trading of minerals. The company activities are focused on the calcium carbonate.

On the basis of international standards, the quality control team of the company controls the manufactured products, since the company should be able to export and compete with the international markets.

Here are four main and important reasons for choosing Emarat Mining Cooperative Company

We are proud to have had the experience of working in the mines since 1989 and now we are at your service with 30 years of experience.

Emarat Mining Cooperative Company has one of the largest calcium carbonate mines in Iran.

The micronizer operation is performed with the best and latest devices in the world and offers the best results.

Emarat Mining Cooperative Company offers the best granulated stones and is a leader in this field.

Below you can see the list of businesses that can use our products. Click on your work to get specific advice for buying calcium carbonate and its processed products suitable for your business.

Send us your business name for a free consultation on how and when to use calcium carbonate.

Calcium carbonate is a natural mineral in the earth’s crust. From an industrial point of view, it consists of three main groups of substances:

Powdered or micronized calcium carbonate (gcc), also called natural calcium carbonate.

Sedimentary calcium carbonate (pcc)

Coated calcium carbonate

In the present plan, we will introduce the products produced by the factory, which is micronized calcium carbonate.

The difference between gcc and pcc

The chemical composition of these two products is the same, the purity of pcc is higher and the amount of silica and lead is less, the shape and size of pcc particles are different from gcc, the shape of gcc particles is often rhombohedral, in the case of pcc the shape of particles depends on how the process is controlled. And the uniformity and uniformity of the particles is greater.

The size range of gcc particles is wider and it shows very large to very small particles, also the size of the largest particles is much larger than the largest pcc particles. With the consumption of pcc, the strength of plastics increases more. The limited dimensional range of pcc particles has increased the oil absorption property for use in certain applications.

Coated calcium carbonate

Coated calcium carbonate is the same as plain calcium carbonate coated with a thin layer of stearic acid (a type of fatty acid). Consumption of this acid is between 0.5 to 3% by weight. Coated calcium carbonate has lubricating properties and acts as a waterproof layer. The type of acid varies depending on the application in the rubber or plastic industry.

Some of the benefits of using coated calcium carbonate powder can be a significant reduction in oil absorption, reducing the accumulation of particles while maximally filling the empty space. Calcium carbonate is coated, coated or coated with stearic acid and is available in various granules.

The latest content published on the site regarding calcium carbonate and related matters, in this section most of your questions have been answered, click on the More Content button to view all articles.

Physical analysis of particle size or the same particle size shows the frequency of particle dimensions in the powder and is usually reported based on

The calcium carbonate as a filler including natural powders and sedimentary products are widely used in various industries; some of the specific ones are gcc

Calcium carbonate ore extracted from the mine is a type of porcelain and the purity of calcium carbonate is 98%. Other elements and associated oxides

Introduction of calcium carbonate The calcium carbonate is a sedimentary rock which is mainly composed of calcite mineral (calcium carbonate: CaCo3). The calcium carbonate is